Skip to Content

Marie Curiestraat 2, 5491 DD Sint-Oedenrode, The Netherlands | +31(0)413-473037 | [email protected]

Language

Emvo.com

Emvo.com

Emvo.com

Emvo.com

-

dk.emvo.com

dk.emvo.com

-

no.emvo.com

no.emvo.com

-

Rotary-vane.com

Rotary-vane.com

-

se.emvo.com

se.emvo.com

-

Emvo.nl

Emvo.nl

-

Pompschoepen.nl

Pompschoepen.nl

-

Druktransmitters.nl

Druktransmitters.nl

-

Vacuummeter.nl

Vacuummeter.nl

-

Digital-manometer.nl

Digital-manometer.nl

-

Digitalemanometer.nl

Digitalemanometer.nl

-

Pressure-gauge.eu

Pressure-gauge.eu

-

Digitalpressuregauge.eu

Digitalpressuregauge.eu

-

druckmessgerät.com

druckmessgerät.com

-

Emvo.de

Emvo.de

-

Bimetallthermometerkaufen.de

Bimetallthermometerkaufen.de

-

differenzdruckmessgerät.de

differenzdruckmessgerät.de

-

Digital-manometer.de

Digital-manometer.de

-

Druckluftmanometer.de

Druckluftmanometer.de

-

Druckmanometerluft.de

Druckmanometerluft.de

-

Druckmanometerwasser.de

Druckmanometerwasser.de

-

Druckmessgerat.de

Druckmessgerat.de

-

Hydraulikmanometer.de

Hydraulikmanometer.de

-

Manometer-kaufen.de

Manometer-kaufen.de

-

Manometerkaufen.de

Manometerkaufen.de

-

Manometerluft.de

Manometerluft.de

-

Manometern.de

Manometern.de

-

Manometerunterdruck.de

Manometerunterdruck.de

-

Manometerwasser.de

Manometerwasser.de

-

Manometerwasserdruck.de

Manometerwasserdruck.de

-

Pumpenlamellen.de

Pumpenlamellen.de

-

Temperaturmessgerat.de

Temperaturmessgerat.de

-

Thermometerkaufen.de

Thermometerkaufen.de

-

Unterdruckmanometer.de

Unterdruckmanometer.de

-

Wasserdruckmessgerat.de

Wasserdruckmessgerat.de

-

Emvo.fr

Emvo.fr

-

Emvo.es

Emvo.es

-

Emvo.it

Emvo.it

Language

Emvo.com

Emvo.com

Emvo.com

Emvo.com

-

dk.emvo.com

dk.emvo.com

-

no.emvo.com

no.emvo.com

-

Rotary-vane.com

Rotary-vane.com

-

se.emvo.com

se.emvo.com

-

Emvo.nl

Emvo.nl

-

Pompschoepen.nl

Pompschoepen.nl

-

Druktransmitters.nl

Druktransmitters.nl

-

Vacuummeter.nl

Vacuummeter.nl

-

Digital-manometer.nl

Digital-manometer.nl

-

Digitalemanometer.nl

Digitalemanometer.nl

-

Pressure-gauge.eu

Pressure-gauge.eu

-

Digitalpressuregauge.eu

Digitalpressuregauge.eu

-

druckmessgerät.com

druckmessgerät.com

-

Emvo.de

Emvo.de

-

Bimetallthermometerkaufen.de

Bimetallthermometerkaufen.de

-

differenzdruckmessgerät.de

differenzdruckmessgerät.de

-

Digital-manometer.de

Digital-manometer.de

-

Druckluftmanometer.de

Druckluftmanometer.de

-

Druckmanometerluft.de

Druckmanometerluft.de

-

Druckmanometerwasser.de

Druckmanometerwasser.de

-

Druckmessgerat.de

Druckmessgerat.de

-

Hydraulikmanometer.de

Hydraulikmanometer.de

-

Manometer-kaufen.de

Manometer-kaufen.de

-

Manometerkaufen.de

Manometerkaufen.de

-

Manometerluft.de

Manometerluft.de

-

Manometern.de

Manometern.de

-

Manometerunterdruck.de

Manometerunterdruck.de

-

Manometerwasser.de

Manometerwasser.de

-

Manometerwasserdruck.de

Manometerwasserdruck.de

-

Pumpenlamellen.de

Pumpenlamellen.de

-

Temperaturmessgerat.de

Temperaturmessgerat.de

-

Thermometerkaufen.de

Thermometerkaufen.de

-

Unterdruckmanometer.de

Unterdruckmanometer.de

-

Wasserdruckmessgerat.de

Wasserdruckmessgerat.de

-

Emvo.fr

Emvo.fr

-

Emvo.es

Emvo.es

-

Emvo.it

Emvo.it

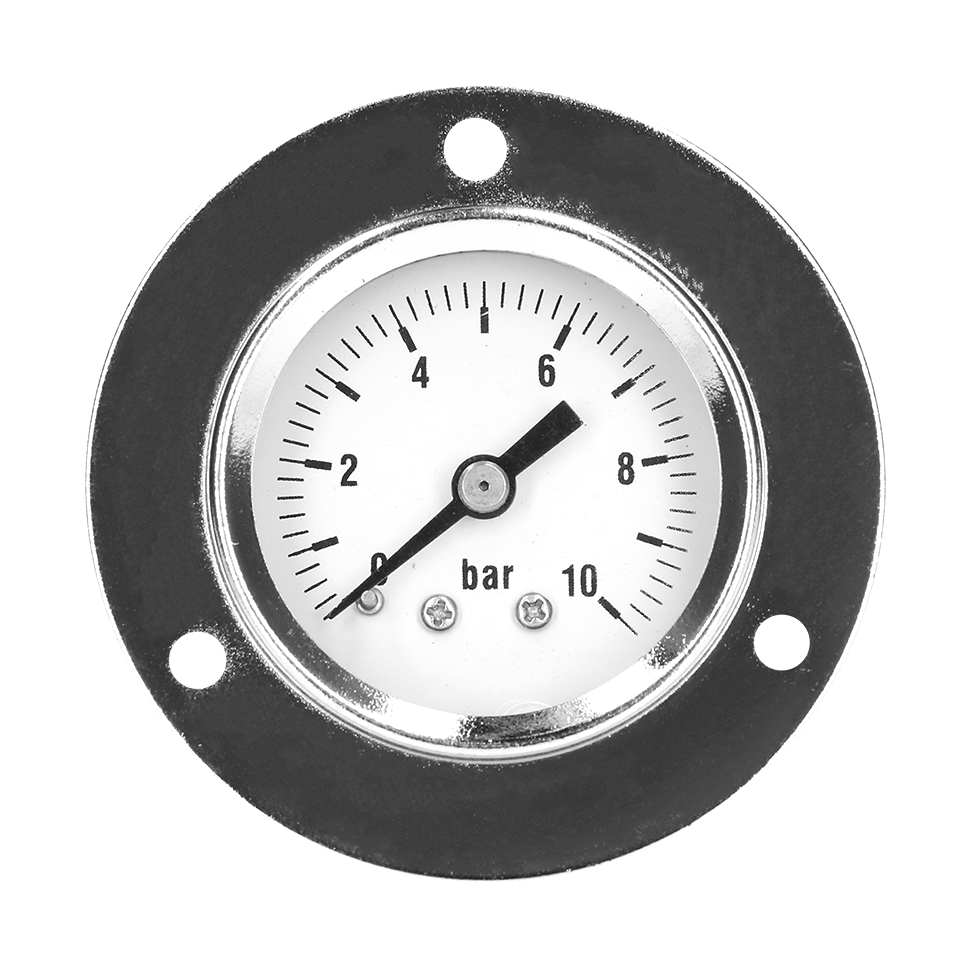

Dry pressure gauges, or aneroid or mechanical gauges, are the most widely used pressure measuring instruments. They measure pressure with an element of elastic metal Pressure will cause the metal to deform, prompting a needle to start moving, accurately indicating the pressure on the scale. Is it possible that vibrations or surges occur in the direct environment of the manometer? In that case, it is better to choose a

Dry pressure gauges, or aneroid or mechanical gauges, are the most widely used pressure measuring instruments. They measure pressure with an element of elastic metal Pressure will cause the metal to deform, prompting a needle to start moving, accurately indicating the pressure on the scale. Is it possible that vibrations or surges occur in the direct environment of the manometer? In that case, it is better to choose a