You can easily find the product that suits you here.

Calibration of pressure gauges: Ultra fast, including report

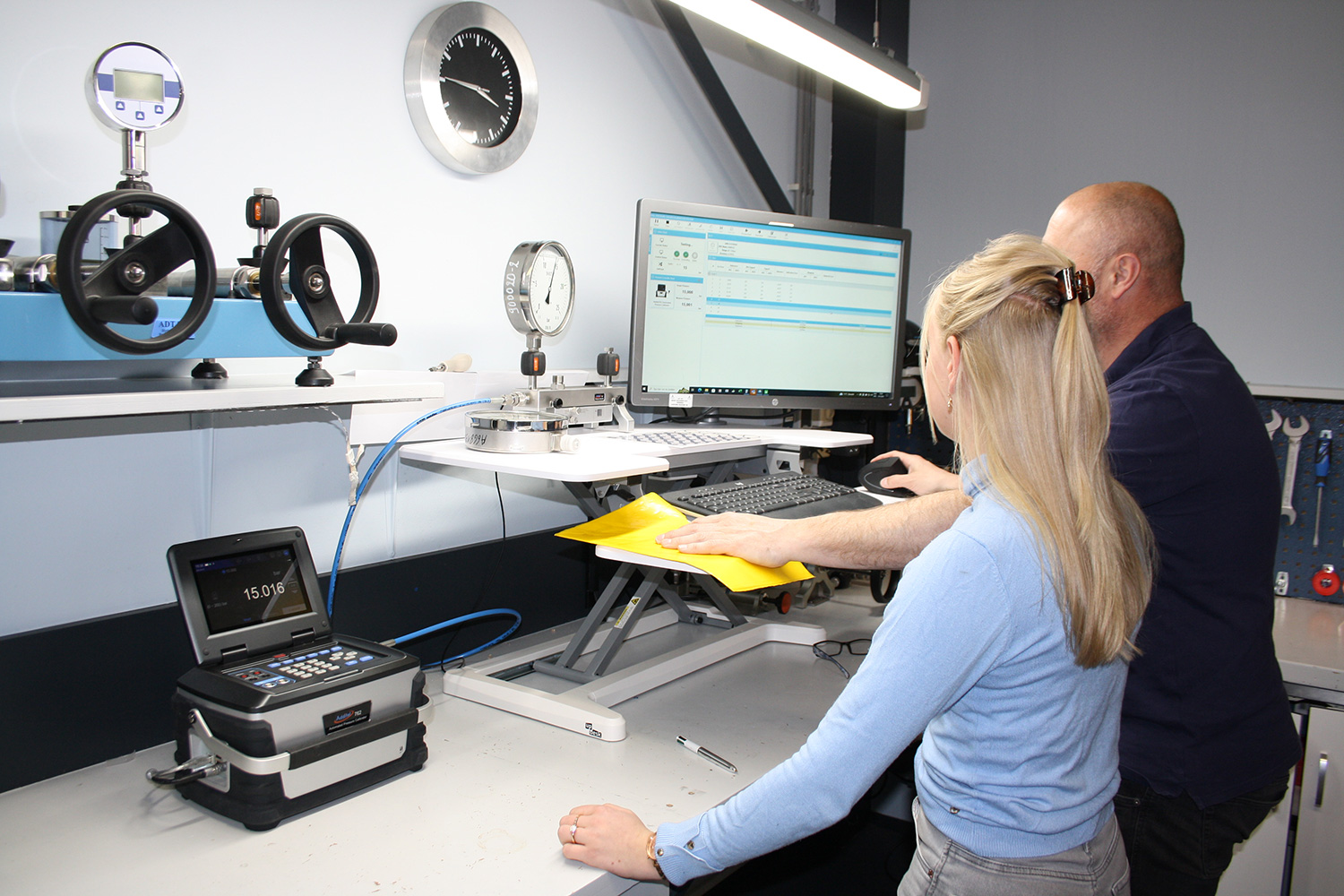

At EMVO Techniek, we calibrate your pressure gauge periodically if you wish so. Thanks to our fully automated calibration station, the process is super fast: upon arrival of your instrument, we can immediately start calibrating and send it back on the same day, including a calibration report.

With over 40 years of experience as a wholesaler and manufacturer, we dispose of both people and knowledge to make sure that your manometers always work perfectly. Would you like to know more about our calibration service? Please contact EMVO Techniek calling +31(0)413-473037, or send us an e-mail.

Pressure gauge repair and revision

EMVO Techniek is also your partner when it comes to repairing or revising your pressure gauges. In our workshop, our technical specialists can repair many defects and malfunctions in your manometer. Do you have a broken pressure gauge? And would you like to know if the defect is repairable? Please, contact us, because we will do everything to make sure you have a perfectly running pressure gauge again.

What is calibration?

When we calibrate a pressure gauge, we compare the error margin of the instrument to an accurate reference measuring instrument. At EMVO Techniek, we have got a fully automated calibrations system. It checks various values within the measuring range of the pressure gauge, including the zero point and the maximum measuring value. If the error margin of the calibrated manometer is too big, an intervention is necessary, so all values end up within the permitted margin. We always supply a calibration report, enabling you (and controlling authorities) to check all calibration data.

Why a pressure gauge should be calibrated

Periodical calibration of pressure gauges is essential. You must be able to rely on the results of your pressure gauge. When the pressure of your measured medium is not displayed correctly, your system can be seriously disrupted, or even damaged. This could cost you a lot of money, but more important: it is a potential danger to the people in the area. Circumstances such as vibrations, pressure peaks and surges, or mechanical tensions, may cause a pressure gauge to become less accurate when time passes, and manometer parts in the mechanical system could be damaged.

How often is calibration necessary?

To guarantee a reliable functioning of the pressure gauge, we strongly advise to calibrate your manometer at least once a year. This is even mandatory if you have to comply to ISO audits and IMO regulations. Therefor, you will always receive a calibration report.

Contact

If you wish, you can get a maintenance contract wit EMVO Techniek; this also applies to pressure transmitters. Do you have any questions about such a contract? Or would you like to find out more about our pressure gauge calibration and repairing service? Please, contact us without any further obligations; we are happy to help you!